General Parameter:

Machinery color: Orange and White

Power supply: 3-phase, 4-wire, 380V, 50HZ

Tube Inside diameter: 94mm

Wall thickness: 7mm

Tube length: 153mm

Speed: 30-35 pcs/min

Edge polishing: Hydraulic

Groove cutting: Straight blade cutting

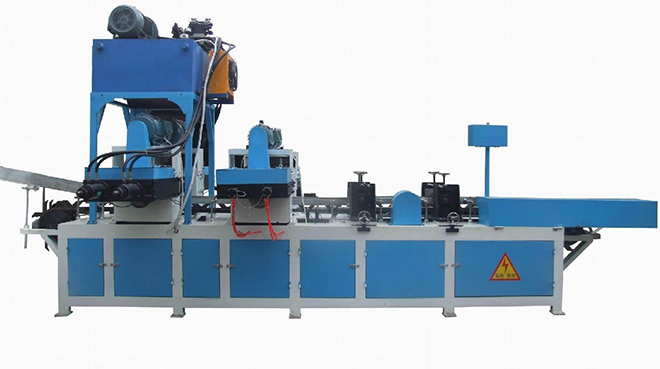

GJQ-E automatic paper tube recutter

Tube Inside diameter: 94mm

Wall thickness: 7mm

Parent tube length: 1600mm

Tube cutting length: 153mm

Number of cutting blades: 11

Speed: 3-4 pcs parent tubes per minute

Parent tube feeding: Automatic

Parent tube unloading: Automatic

Blade adjustment: Blade sleeve

Cutting mandrel: Nylon mandrel

Working description: One operator load the parent tubes on the paper tube holder,

the paper tube will be feeded on the mandrel automatically, the motor drives the blades rotating and cutting the tubes.

The cores unloading unit unloads the recut cores on the transporting line,

and the second parent tube prepared to feed on the mandrel and cut.

Transporting line

Transporting line 2

Transporting motor: 0.2 KW per set

Height adjustment: Manual adjustment

Working description: Connecting the paper tube cutter and the full-automatic POY tube finishing line,

transport the recut cores to the finishing line. In the feeding point of the finishing line,

use the cylinders to apply the lubricate oil on the both edges of the core.

Full-automatic POY paper tube finishing machine

Technical specification:

Tube Inside diameter: 94mm

Wall thickness: 7mm

Tube length: 153mm

Speed: 30-35 pcs/min

Groove cutting: Straight blade cutting

Edge polishing motor: 2.2KWx2

Groove cutting motor: 1KW servo motor

Transporting motor: 1KW servo motor

Working description: The transporting line feed the cores to the fininshing line, the servo motor drives the core to edge polish.

The cores are heightened to the right height automatically, the both edge polishing heads start to polish the core edges via

the hydraulic pressure, and the polished core will be lowered down and go ahead to the groove cutting position.

The core positioning unit fixes the right position of the core, after the right positioning, the groove blade start to cutting under

the driving of the servo motor. At the same time, the core surface polishing wheel is polishing the core surface.